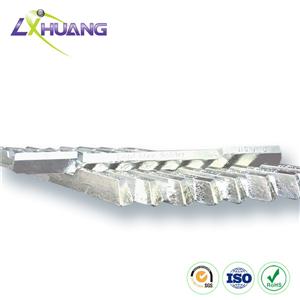

High Temperature Alloy Solder

-

-

superior performance, low cost, high purity, excellent solderability, good wetting, strong anti-oxidization,Sn-Sb solders (tin antimony solder alloys) are featured by superior performance, low cost, high purity, excellent solderability, good wetting, strong anti-oxidization, and so on.

-

-

TV sets, computers, radios, and so on. Factors, such as melting point, plastic range, wetting speed, wetting ability, soldering methods, etc.Factors, such as melting point, plastic range, wetting speed, wetting ability, soldering methods, etc. must be considered when electing the proper lead-free solder alloy.

-

-

The tin antimony solder rods are widely used in soldering metal equipments for TV sets, radios, home appliances, radio transponders, instruments, computers,To fulfill practical applications, operators should choose right brazing filler metals ect。

-

-

Sn-Cu alloy solder has replaced the lead solder and widely works for soldering electronic elements and fix the silicone products,Sn99.3Cu0.7 is available in both wave soldering and dip soldering, because it is eco-friendly and meets high demands for environmental protection.

-

-

Sn-Cu alloy wires are widely used because of favorable electrical conductivity, high melting point, low cost, reliable working performance and many other advantageous features.These Sn-Cu alloy wires are widely used because of favorable electrical conductivity, high melting point, low cost, reliable working performance and many other advantageous features.

-

-

Although Tin silver copper alloy solders are in more expensive than Sn-Cu solders, they are still widely applied in lead-free automatic wave soldering and other soldering processes because of good wettability and thermal resistance.

-

-

This tin silver copper alloy solder wire/bar/rod (Sn99Ag0.3Cu0.7) is also known as SAC0307 lead-free solder. It is applicable for precise LED, mobile phone chips, PCBs, etc. in many hi-tech wave soldering machines and small-sized tin furnaces.

-

-

The main requirements for the connection, but the strength of the small joints, such as electronic equipment, instruments, household appliances electronic circuits, computer chips, cell phone chips, stainless steel, lead, PCBs and other joints.

-

-

Tin is used to solder electrode welding rod. At elevated temperature and pressure conditions are not required to be used to seal solder metal welding. , Has good antioxidant capacity, high mobility, strong welding, scum rarely melts, and wave soldering immersion little oxidation, the provincial economy tin solder. Excellent wettability and solderability, solder full, uniform, welding with excellent results.

-

-

Sn-Ag lead free solder is featured with high melting point and strong thermal strength. As professional tin silver alloy solder maker, we provide various Sn-Ag solders.The Sn/Ag series solders are widely used in soldering electronic assemblies; besides, it is applicable for soldering of jewelry due to its solder point is of high brightness.

-

-

This kind of Sn-Ag lead-free soldering wire/bar (Sn95Ag5) is applicable for soldering electronic elements in TV set, radio, instruments, transformers, computers and common home appliances.It features good mechanical performance, good fluidity, high thermal fatigue resistance, etc.

-

-

Adopting lead-free technology, environmental protection, lead-free solder bar is usually in the weld metal equipment, copper pipe, copper plate, etc.Sn-Cu lead-free solder bars are commonly used in soldering metal equipments, copper tubes, copper plates, and so on.

Introduction

High temperature

alloy solder usually works in bad environment, which requires many aspects

should meet strict conditions. For example, the solder should be qualified for

high heating and hardly be negatively affected; besides, the soldered joint

should meets demands for thermal treatment after welding. As professional

tin-based alloy manufacturer, we provide various solder bars/wires made from

Sn-Sb alloy (Sn95Sb5), Sn-Cu alloy (Sn97Cu3,

Sn99.3Cu0.7, Sn99.3Cu0.7), Sn-Cu-Ag

alloy (Sn92Cu6Ag2, Sn99Cu0.7Ag0.3)

and Sn-Ag alloy (Sn95Ag5).

Features

1. Our

high temperature alloy solder shows excellent performance in flux, melting

rate, and flowability.

2. Flux

is uniformly distributed and of good continuity.

3. Few

smoke and gas generates.

4. With

strong resistance to high heat, it can remain flossy silver surface even under

high temperature.

5.

Featured by superior anti-oxidization, it produces just a little solder

splatter.

6. High

temperature alloy solder is widely utilized in welding components for radio,

communication equipments, meters, instruments, etc.

7. Due to

good malleability, the internal stress (caused by thermal expansion) is

reduced.

Notes

Solidus and liquidus

vary with different high temperature alloy solders